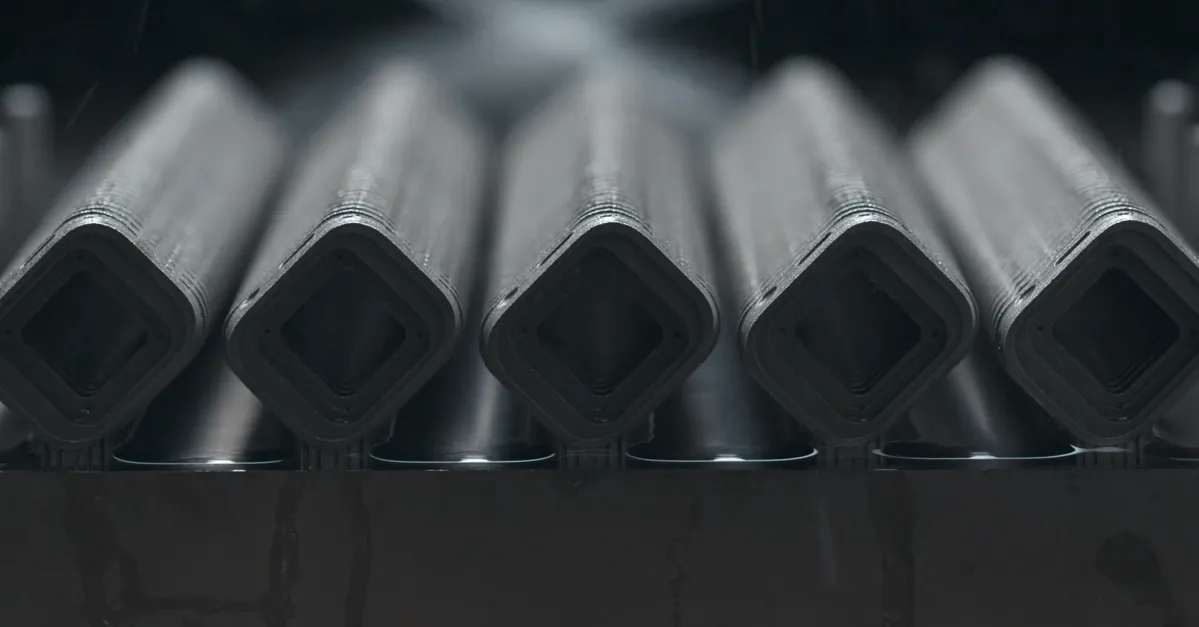

When you evaluate the Apple Watch Ultra 3 with the Ultra 2, you most likely wouldn’t be capable to inform they had been made with drastically completely different manufacturing processes. The titanium Apple Watch Series 11 and Extremely 3 will not be solely made with one hundred pc recycled titanium powder, however are additionally 3D-printed, a course of that’s fairly spectacular at Apple’s scale. 3D printing creates much less waste, on this case slicing uncooked supplies utilization for the watch circumstances in half, however introduces new challenges, like balancing velocity and precision.

Apple has released more details about its course of, which entails blasting titanium mud with a laser. Over 900 layers of fabric, every 60 microns thick, go right into a single watch case (for context, one micron is the same as 0.001 millimeters). The titanium powder used for the circumstances must be fine-tuned itself to scale back its oxygen content material so it gained’t explode when uncovered to excessive warmth.

Printing Watch circumstances, quite than utilizing subtractive manufacturing, has allowed Apple to avoid wasting an estimated 400 metric tons of uncooked titanium this 12 months. Apple additionally utilized the identical 3D-printing course of to the USB-C port on the iPhone Air. Whereas they’re not 3D-printing a whole iPhone chassis but, it sounds prefer it’s not out of the query. As Sarah Chandler, Apple’s VP of atmosphere and provide chain innovation, mentions within the press launch, “We’re by no means doing one thing simply to do it as soon as — we’re doing it so it turns into the best way the entire system then works.”